Blister Sealing Machinery

The blister sealer is basically a hot plate that presses the blister card and vacuum formed blister together with heat. Theoretically, if you could apply enough pressure, a clothing iron would do the job. However, it’s a lot more practical to buy a blister sealer and sealing tool.

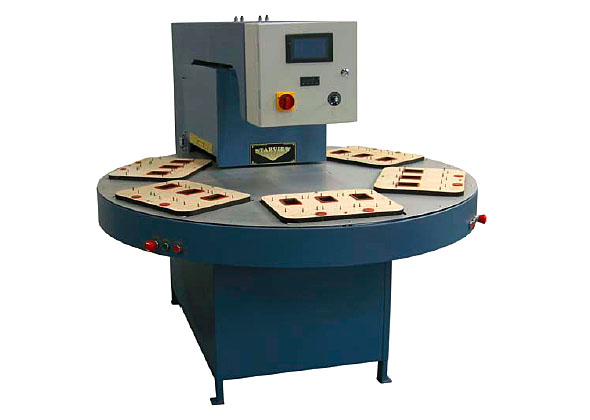

The main difference between blister sealers is the number of loading stations. More stations allows you to break the loading process into smaller pieces and also allows the loading to take place during the sealing cycle.

The anvil to the sealers’ plate is called a sealing tool. It is a tray with a cavity cut into it to accomodate the specific blister size and shape. The opening on the tray is just large enough to fit the molded part of the blister, but keeps the flat part to be sealed against the card. The card is located (face down) on top of the sealing tool with spring loaded pins to locate the card properly.

We can help you pick the right machine for you, whether you buy it from us or not. Give us a call and describe your project, we’ll be glad to lend a hand. We’ve been selling and building blister sealers for almost 40 years. By now, we know what we’re doing!

Get a Quote

Our professionals will be happy to discuss what you need done and how we can help ensure it is done the way you want.